Everything You Need to Know About Chimney Flashing

If you own a chimney in your home, you probably already know that it requires a certain level of care and maintenance to keep it safe, efficient and problem-free.

You might also know that chimney leaks can be one of the most troublesome issues your chimney can face. Luckily, there are a few simple things you can do to protect it from future damage - one of which is chimney flashing.

Are you unsure of exactly what chimney flashing is and how it is installed? Read our guide for everything you might need to know...

What is Chimney Flashing?

Chimney flashing is a protective layer of sheet metal or lead that seals the join between the chimney and the roof. It’s purpose is to ensure no moisture can leak into the gap that would otherwise be there, which, if left unflashed, would result in issues with damp, rot and other types of water damage.

Is Chimney Flashing Necessary?

You might not think chimney flashing is that important, but it is a completely necessary part of any chimney construction. If you were to try going without chimney flashing, you would soon notice rain water leaking into your attic or damp patches appearing on your ceiling, walls or chimney breast.

If left untreated, the water damage caused by a leaking chimney can even lead to structural damage, so it’s vital that your flashing is doing its job properly.

How Long Should Chimney Flashing Last?

The good news is that chimney flashing is often incredibly durable if installed professionally, and can last up to 30 years!

In order to make sure your flashing lasts as long as possible, regular inspections and maintenance is key. You should have your chimney swept at least once a year anyway, so if any signs of damage are found, it will cost you far less in the long term to get it patched up sooner rather than later.

What Types of Chimney Flashing Are There?

There are a few different types of chimney flashing materials available to suit different chimney requirements, including:

- Aluminium

- Steel

- Copper

- Flexible EPDM

- Lead

For traditional brick chimney stacks, sheets of aluminium, steel, copper or lead are usually cut into the required size to fit around the base of the chimney.

For twin wall flue installations, the flashing is installed a little differently - we’ll explain more below...

How to Do Flashing Around a Chimney

First of all, we should start by saying chimney flashing is a job best left to a professional roofer. We don’t recommend doing any work up on your chimney without the proper safety equipment - plus, you would need some rather specialist tools to properly fit your flashing!

Flashing for a traditional chimney stack

To do flashing around a traditional chimney, pieces of correctly sized aluminium, steel, copper or lead are bent around the chimney stack, forming a join with the roof.

First, base and step flashing is applied, which sits under the roof shingles and is bent upwards into an L-Shape up the side of the chimney.

Then, counter flashing is placed on top to ensure there is no gap. For this, the mortar between the bricks is chiseled away, so that the flashing can be embedded into the brickwork. Again, it is bent into the correct shape before being sealed into position.

The aim for flashing around a chimney is to ensure there is a watertight seal that prevents rain from entering from any direction. This is why multiple pieces of flashing are assembled, to ensure that it sits flush with the roof slope and that there are no gaps where moisture can leak through.

Flashing for a twin wall flue system

As twin wall flue systems are cylindrical, they can’t be flashed in the same way as a traditional chimney stack.

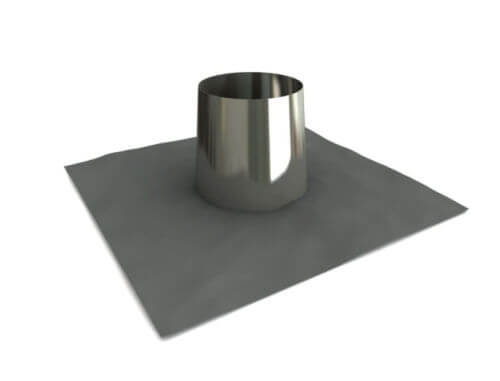

So instead of cutting out sections of flashing and laying them around the chimney, you can fit a pre-cut pipe flashing.

There are two options you can choose from:

Each one comprises a malleable base with either a silicone or stainless steel cone for the flue pipe to fit through.

If you choose one of our flexible EDPM pipe flashings, you can simply cut the required size hole in the silicone cone you need for your flue pipe to pass through. The aluminium sheet base can be adjusted to fit tile and slate roofs, too.

Our lead flue pipe flashing works in a similar way, but with a lead sheet base instead of aluminium. They also use a stainless steel cone instead of adjustable silicone, so you need to make sure you choose one with the same diameter as your flue pipe.

They come in varying roof pitch angles, so you also need to find the correct angle for your particular roof.

Also available at Trade Price Flues is the innovative new Dura Flash - an ideal eco-friendly alternative to lead that is incredibly quick and simple to install. These easy to use flashings can be fitted underneath tiles or stuck down to any dry surface, thanks to the stretchable material they are produced from.

See how easy they are to adhere to roof tiles here:

Do you have a chimney that needs flashing? Whatever type of chimney you have, you can simply give us a call and our expert team at Trade Price Flues will help you find exactly what you need.

Contact Trade Price Flues

Find more chimney advice on the Trade Price Flues blog…

How Do You Fit a Chimney Liner? | What is a Twin Wall Flue System? | Do You Need a Cowl on Your Chimney?

Latest Articles

-

Air Pollution Down in the UK Despite Record Wood Burner Sales

Great news! Wood-burning stoves, once considered environmental villains, have transformed into eco-f …18th Apr 2024 -

A Guide to Stove Installation in Lodges, Sheds, and Shepherd’s Huts

Shepherd’s huts, lodges, and sheds have become increasingly popular as charming retreats or alternat …25th Mar 2024 -

Pinned vs. Pinless Moisture Meters: Which is Best for Firewood?

When you collect or buy firewood, it usually starts very moist inside. Using sopping wet wood to bur …4th Mar 2024